High-Power Series

It can support a current of 150A and is suitable for various high-power applications, such as new energy vehicles, medical equipment, LED displays, and other industries.

Product features:

● Power: Rated current up to 150 A;

● High cycle life: Ensures a plug-and-play lifespan of 10,000 cycles

● Supports mixed installation with standard current signals: The connector is compatible with multiple signal types for mixed installation;

● Safety assured: The contact points feature built-in black rubber rings to prevent electric leakage.

● Convenient disassembly and assembly: Equipped with matching needle-removal tools and crimping tools, making it easy for customers to operate and use.

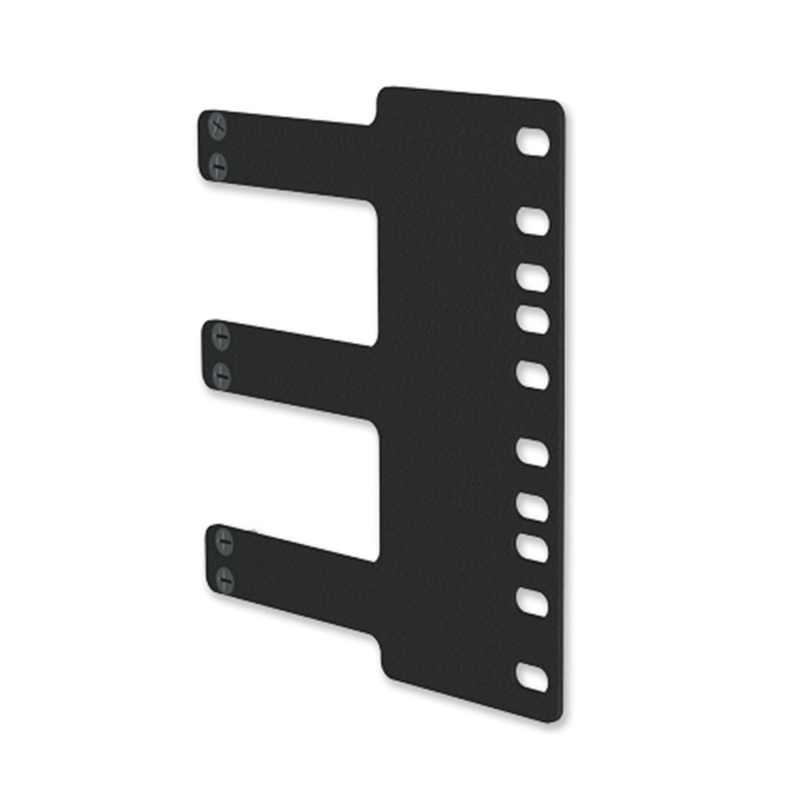

According to the corresponding pinhole, the number of modules to choose the appropriate frame

According to the type: power supply, signal, data, coaxial, optical fiber, pneumatic and fluid, etc.; According to the signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; According to the cable connection mode: crimping, welding; According to the corresponding pinhole, there will be a corresponding module selection, and the number of signals to select the corresponding module.

According to the corresponding pinhole, the number of modules to choose the appropriate frame

According to the type: power supply, signal, data, coaxial, optical fiber, pneumatic and fluid, etc.; According to the signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; According to the cable connection mode: crimping, welding; According to the corresponding pinhole, there will be a corresponding module selection, and the number of signals to select the corresponding module.

According to the selected pinhole module frame, select the appropriate supporting tools and accessories

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting corresponding modules based on the number of signals.

Select appropriate supporting tools and accessories based on the chosen pinhole module framework.

Select the appropriate frame based on the corresponding number of pinholes and modules.

According to type: power, signal, data, coaxial, optical fiber, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then, based on the corresponding pinholes, there will be corresponding module selections, as well as signal quantity selections corresponding to the modules.

Select appropriate matching tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, optical fiber, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting corresponding modules based on the number of signals.

Select appropriate supporting tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting the corresponding module based on the number of signals.

Select appropriate supporting tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting the corresponding module based on the number of signals.

Select appropriate supporting tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting the corresponding module based on the number of signals.

Select the appropriate supporting tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting the corresponding module based on the number of signals.

Select appropriate supporting tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting corresponding modules based on the number of signals.

Select appropriate supporting tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting the corresponding module based on the number of signals.

Select the appropriate supporting tools and accessories based on the chosen pinhole module framework.

CMV01229-H30 High-Power Male Pin, Contact Type, ITA, 150 Amp, 2 AWG, 30µ Gold Plated

CMV01129-H60 High-Power Female Terminal, Contact Type, Receiver, 150 Amp, 2 AWG, Silver-Plated 60µ

CMV08414 Tri-Signal/High-Power Module, ITA, F Series, 4/4 Channel

CMV08314 Tri-Signal/High-Power Module, Receiver, F Series, 4/4 Channels

CMV08226 Tri-Signal/High-Power Module, ITA, V Series, 6/6 Channels, Includes Stress Plate

CMV08126 Tri-Signal/High-Power Module, ICA, V Series, 6/6 Channels, Includes Stress Plate

CMV09014 Stress Plate, ITA, and Receiver, V Series, 150A High-Power

CMV06007 Tools, Crimping Tool Kit, High-Power, ICA and ITA Terminals

CMV06207 Tools, Retractors, Receivers, and ITAs, 150A High-Power