High-Speed Series: TPDC

With the advancement of bus technology, high-speed applications have become widespread—from military drones to commercial multimedia displays and automotive electronics. As a result, the demand for testing speeds has also evolved from Mbps to Gbps.

In the test: 1. How to ensure signal integrity;

2. How to jump from Mbps to Gbps;

3. How to ensure the product’s service life.

The TPDC CMV high-speed series connection solution launched by Tengfang Zhongke precisely meets the three requirements mentioned above.

According to the corresponding pinhole, the number of modules to choose the appropriate frame

According to the type: power supply, signal, data, coaxial, optical fiber, pneumatic and fluid, etc.; According to the signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; According to the cable connection mode: crimping, welding; According to the corresponding pinhole, there will be a corresponding module selection, and the number of signals to select the corresponding module.

According to the corresponding pinhole, the number of modules to choose the appropriate frame

According to the type: power supply, signal, data, coaxial, optical fiber, pneumatic and fluid, etc.; According to the signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; According to the cable connection mode: crimping, welding; According to the corresponding pinhole, there will be a corresponding module selection, and the number of signals to select the corresponding module.

According to the selected pinhole module frame, select the appropriate supporting tools and accessories

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting corresponding modules based on the number of signals.

Select appropriate supporting tools and accessories based on the chosen pinhole module framework.

Select the appropriate frame based on the corresponding number of pinholes and modules.

According to type: power, signal, data, coaxial, optical fiber, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then, based on the corresponding pinholes, there will be corresponding module selections, as well as signal quantity selections corresponding to the modules.

Select appropriate matching tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, optical fiber, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting corresponding modules based on the number of signals.

Select appropriate supporting tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting the corresponding module based on the number of signals.

Select appropriate supporting tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting the corresponding module based on the number of signals.

Select appropriate supporting tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting the corresponding module based on the number of signals.

Select the appropriate supporting tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting the corresponding module based on the number of signals.

Select appropriate supporting tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting corresponding modules based on the number of signals.

Select appropriate supporting tools and accessories based on the chosen pinhole module framework.

Choose the appropriate frame based on the corresponding pinhole and the number of modules.

According to type: power, signal, data, coaxial, fiber optic, pneumatic, and fluid, etc.; according to signal characteristics: voltage, current, power, frequency, pressure, rate, etc.; according to cable connection methods: crimping, welding; then based on the corresponding pinholes, there will be corresponding module selections, as well as selecting the corresponding module based on the number of signals.

Select the appropriate supporting tools and accessories based on the chosen pinhole module framework.

CMV08430 Qua signal module, ITA, SIM, 4 channels

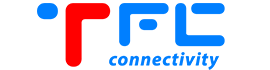

T216921000-xm signal jumper, ITA, TPDC to high temperature shielded twisted pair, 26AWG, x meters

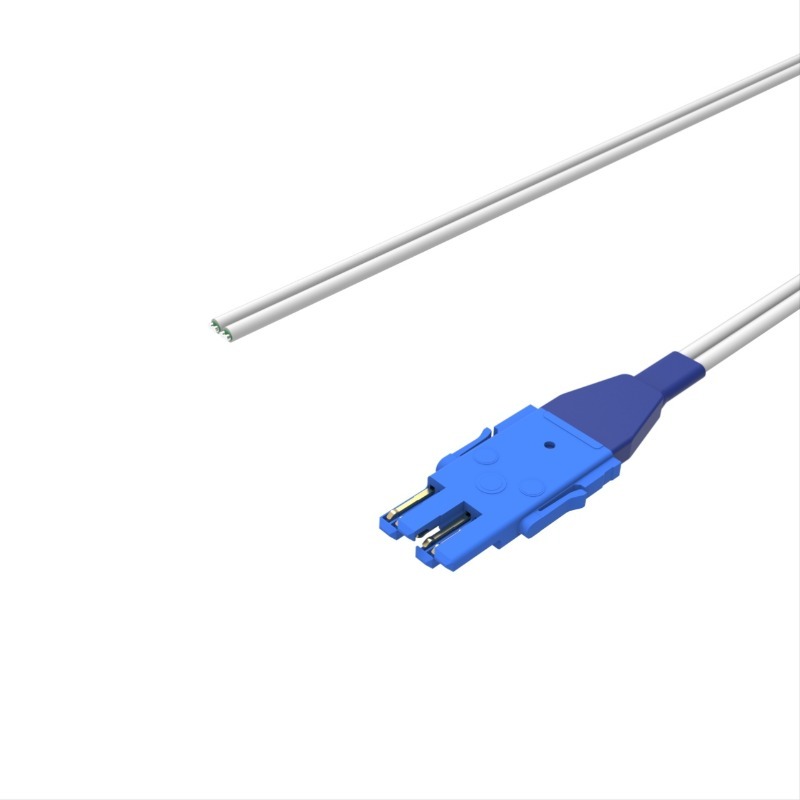

T216920233-xm signal jumper, ITA, TPDC to CAT7 network cable plug, x meters

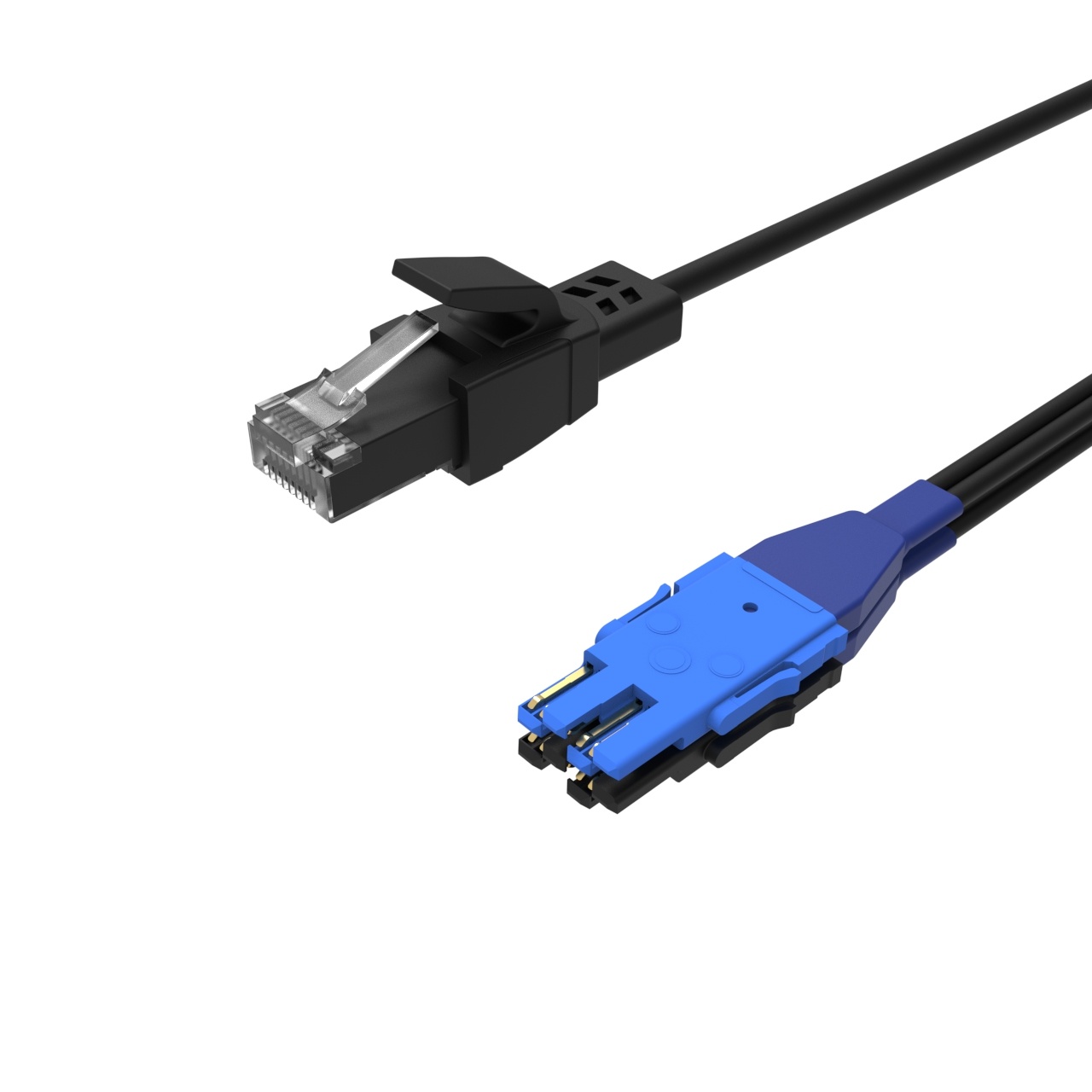

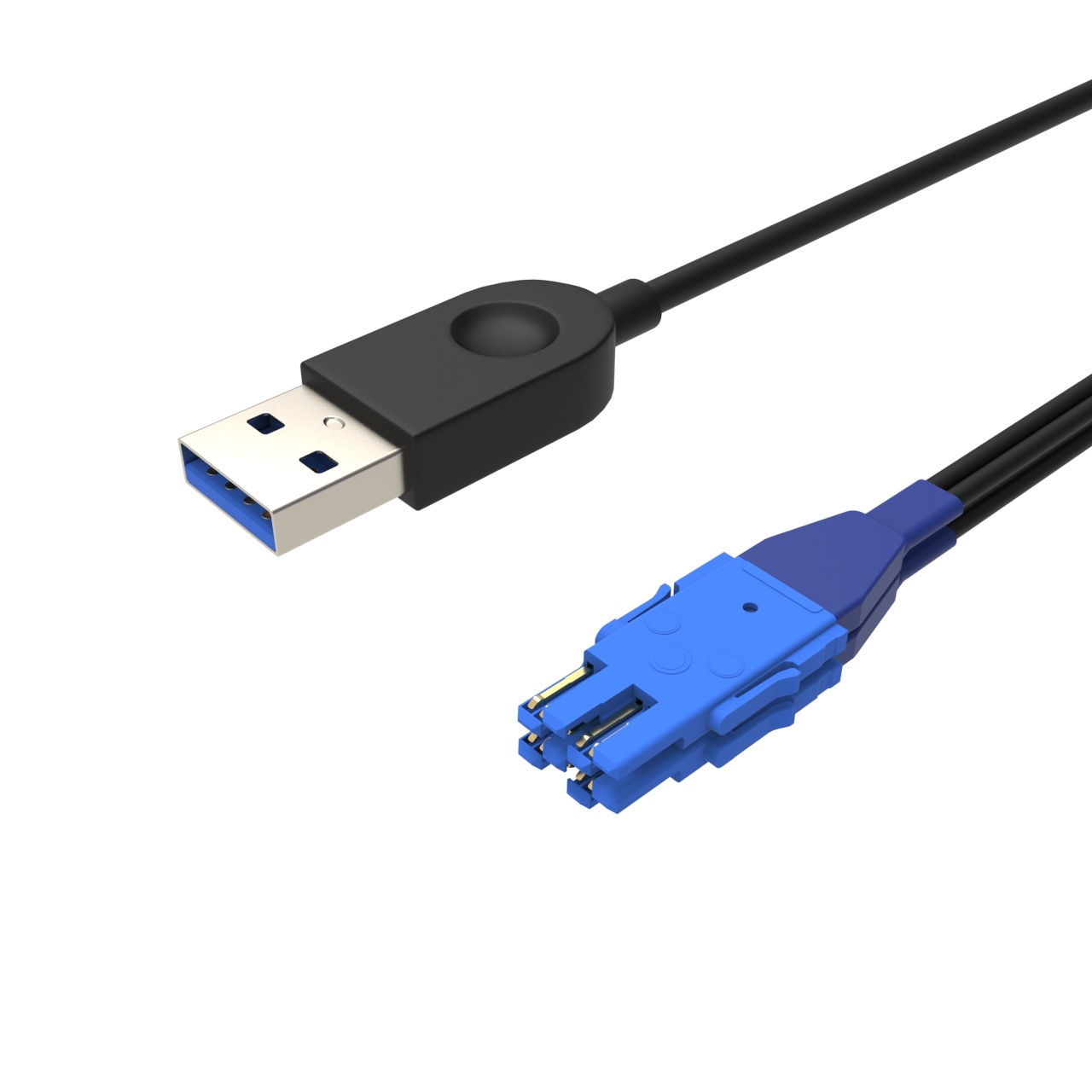

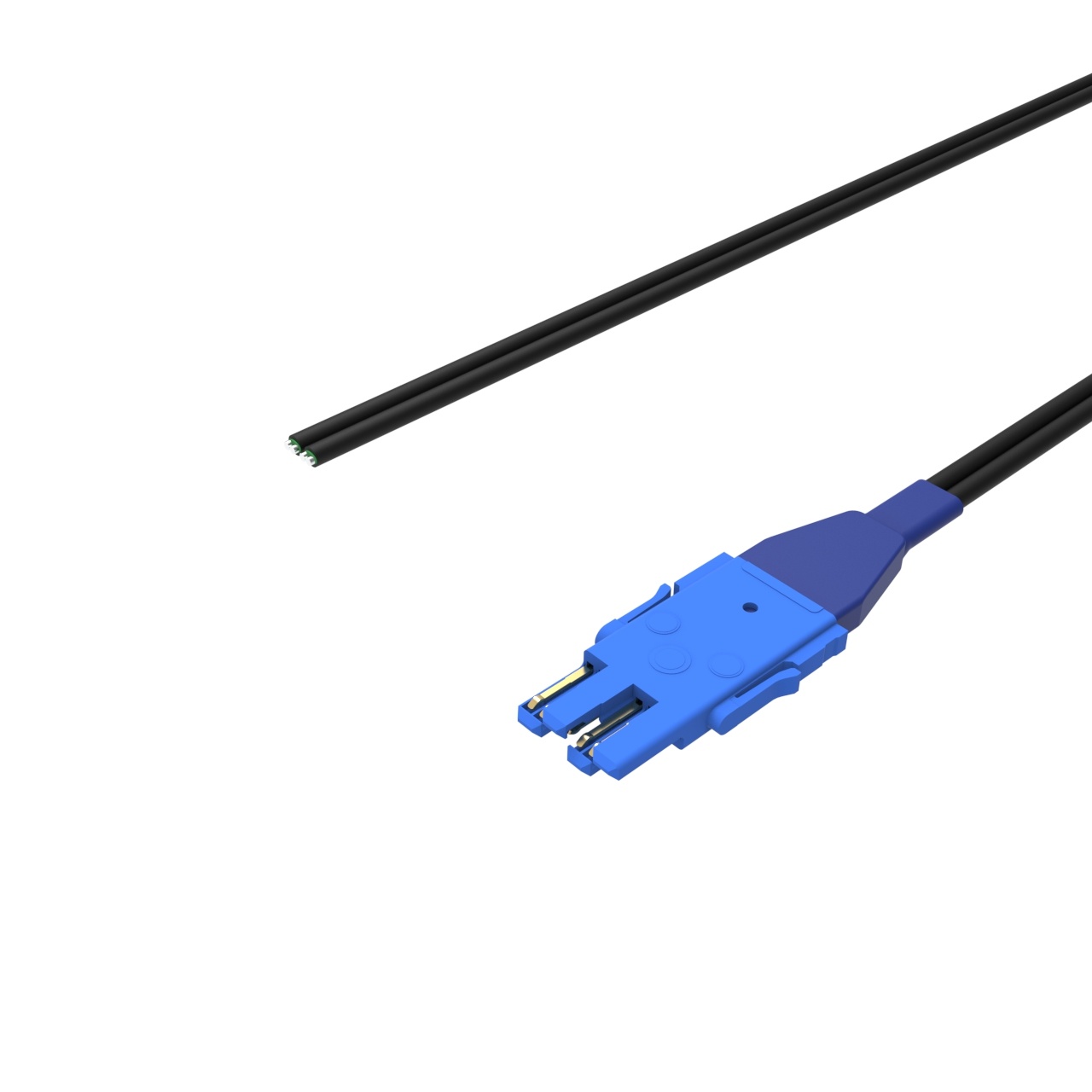

T216918231-xm signal jumper, ITA, TPDC to USB3.2 Gen1 socket, x meters

T216919232-xm signal jumper, ITA, TPDC to HDMI 2.0 plug, x meters

T216918230-xm signal jumper, ITA, TPDC to USB3.2 Gen1 plug, x meters

T216916000-xm signal jumper, ITA, TPDC to shielded twisted pair, 28AWG, x meters

CMV01155 High-speed signal terminal, ICA/ITA, 4 pairs 8 cores, 1 slot (sold only in jumper form)

CMV08330 Qua signal module, ICA, SIM, 4 channels

T213921000-xm signal jumper, ICA, TPDC to high temperature shielded twisted pair, 26AWG, x meters

T213920233-xm signal jumper, ICA, TPDC to CAT7 type network cable plug, x meters

T213919232-xm signal jumper, ICA, TPDC to HDMI 2.0 plug, x meters

T213918230-xm signal jumper, ICA, TPDC to USB3.2 Gen1 plug, x meters

T213916000-xm signal jumper, ICA, TPDC to shielded twisted pair, 28AWG, x meters

T213918231-xm signal jumper, ICA, TPDC to USB3.2 Gen1 socket, x meters

CMV01155 High-speed signal terminal, ICA/ITA, 4 pairs 8 cores, 1 slot (sold only in jumper form)

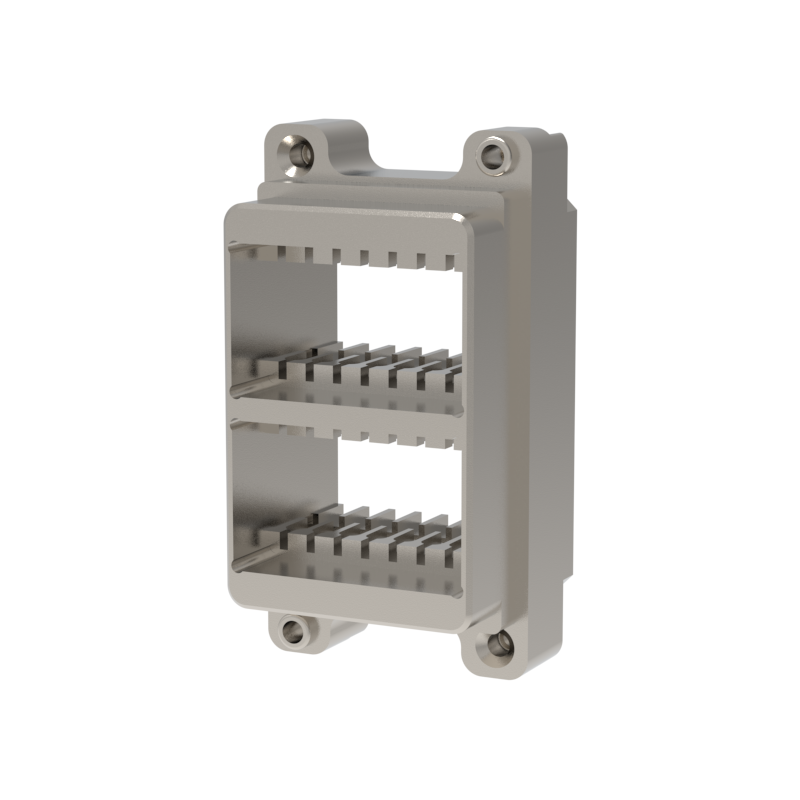

CMV08428 TPDC, module, ITA, F series, 16 positions

CMV08328 TPDC, module, ICA, F series, 16 positions

CMV08243 High-speed signal module, ITA, V series, 34 slots, 272 points

CMV08143 High-Speed Signal Module, ICA, V Series, 34 Slots, 272 Points

CMV06217 Needle-retraction tool, Qua, SIM receiver

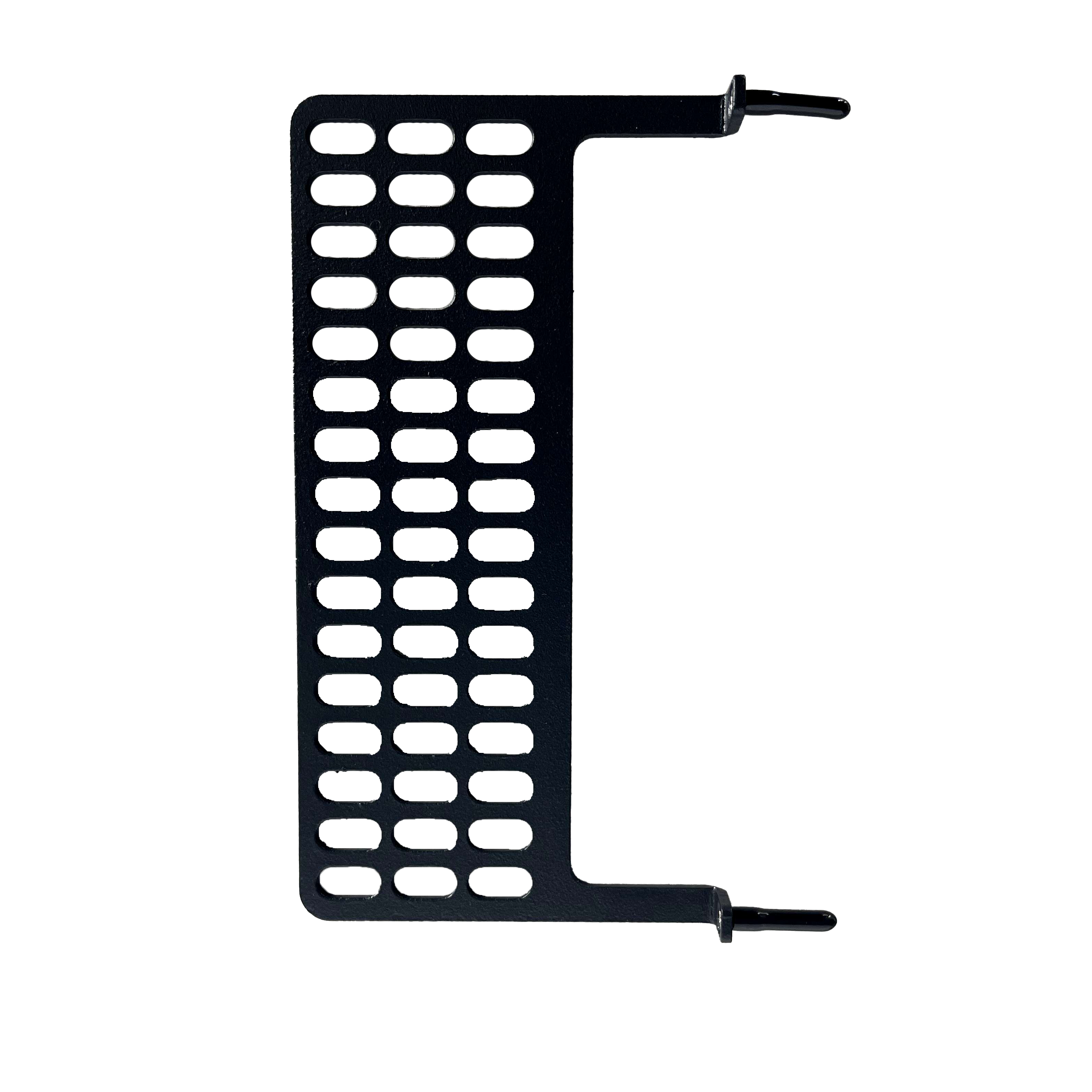

CMV09071 Stress Plate, High-Speed Signal Module, ICA/ITA, Compatible with Harness Solutions

CMV06209 – Exit tool for high-speed signal terminals, ICA/ITA

CMV01154 High-speed terminal filling block